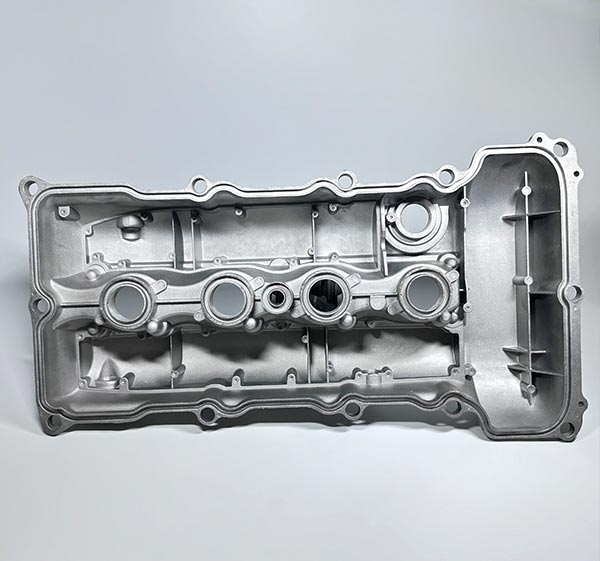

Our aluminum casting auto parts are produced with the highest precision and efficiency. Using state-of-the-art machinery, we achieve detailed and intricate designs, ensuring perfect fit and function in your vehicle. Our parts feature a powder coat finish. This process ensures an even layer of paint, enhancing resistance to wear, corrosion, and fading. This makes them easy to maintain.

Losier Technology Development Co., Ltd. is a manufacturer based in Hebei, China. This region is renowned for its expertise in precision manufacturing and automotive parts production. We leverage local expertise to bring you the highest quality, competitively priced aluminum casting auto parts. Made from premium cast aluminum, these components are designed to withstand the rigors of daily use, and their rugged construction makes them a reliable choice for long-lasting performance and durability. We are the professional casting supplier you've been looking for.

| Features | Technological Breakthrough | User Value |

| Ultimate Lightweight | Aluminum density of 2.7g/cm³ (only 1/3 that of steel) | Vehicle weight reduction of 15-20%, range improvement of 10%+ |

| Revolutionary Strength | Nano-reinforced aluminum alloy with a tensile strength of 380MPa | Crash safety exceeds national standards by 200% |

| Precision Integration | Integrated die-casting reduces joints by 90% | Failure rate reduced by 30%, assembly costs reduced to zero |

| Superior Corrosion Resistance | Micro-arc oxidation coating withstands 1000 hours of salt spray | Lifetime corrosion protection, lifespan extended to 15 years |

| Product Name | Casting parts |

| Material | Gray cast iron, ductile iron, malleable iron, carbon steel, alloy steel, stainless steel, Steel, aluminum, bronze, brass, A356, A360, A380, ADC12, SS304 |

| Surface Treatment | Electrogalvanizing, hot-dip galvanizing, electrophoresis, powder coating, painting, sandblasting, anodizing, etc. |

| Heat Treatment | Induction furnace for heating raw materials. Capable of continuous quenching, tempering, and carburizing heat treatment. |

| Standards | JIS, DIN, ASTM, BS, GOST |

| Process | Sand casting, investment casting, precision casting, forging, stamping, CNC machining. |

| Drawing Format | jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t.etc |

| Services | Provide production design, production and technical services, mold development, and machinery. |

| Testing Machine | Digital altimeters, calipers, coordinate measuring machines, projectors, roughness testers, hardness testers, salt spray testers, etc. |

Q1: Can die-casting replace welded steel structures?

Absolutely! Our integrated die-cast crossbeam has passed a frontal impact test (64 km/h), absorbing 35% more energy than steel.

Q2: How to address surface roughness on sand castings?

Using zircon powder coating + CNC shot peening, the Ra value can be reduced from 25μm to 6.3μm (mirror-grade).

Q3: How to control costs with an annual production volume of only 10,000 units?

Recommended composite process: sand casting of the main body + die-cast inserts for key areas. Mold investment can be kept below $120,000.