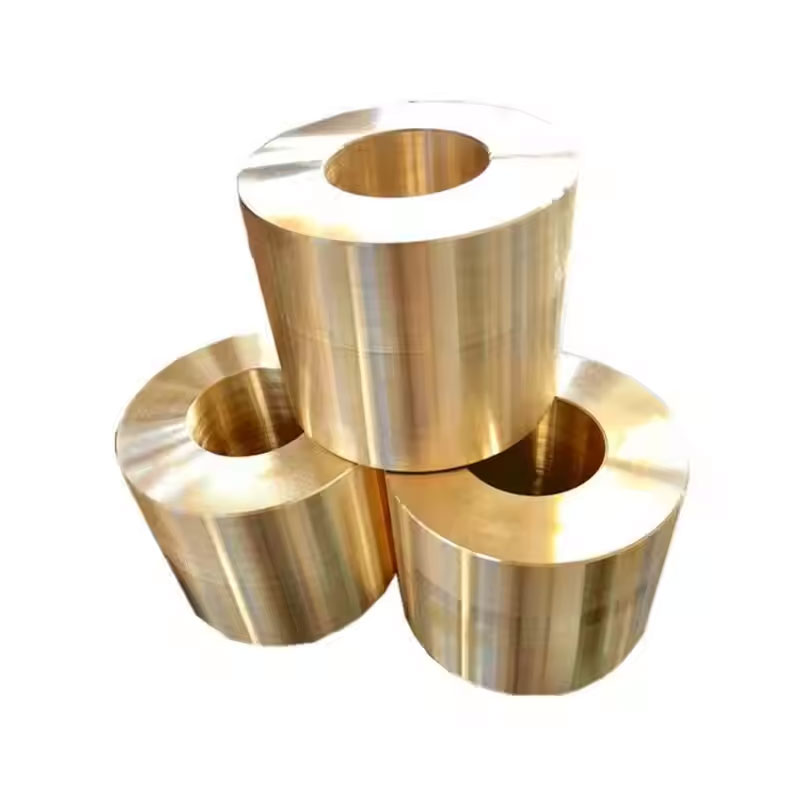

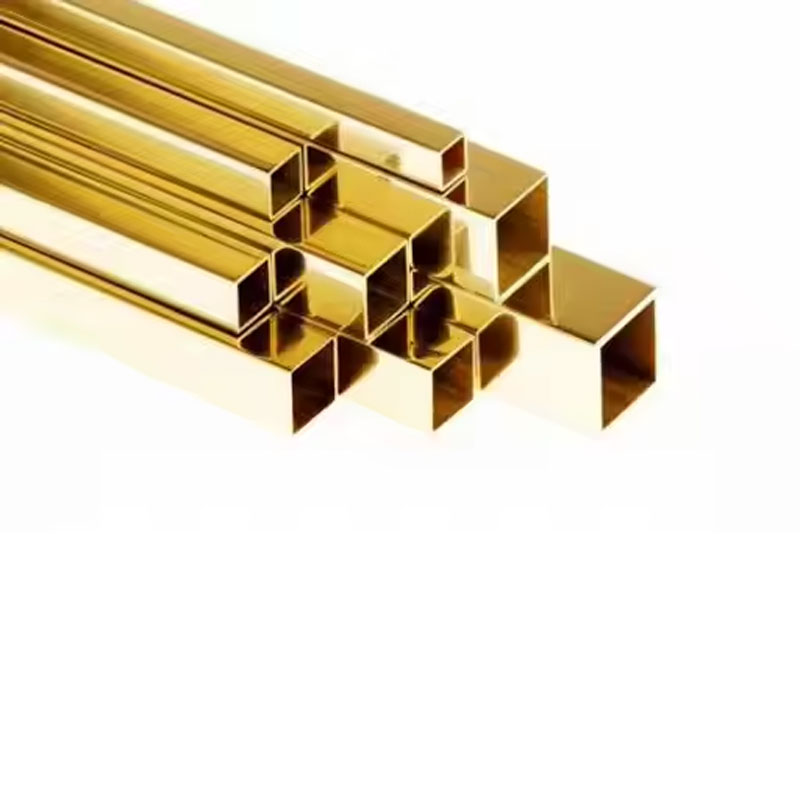

Our custom Brass Sand Casting with Blasting Brass Pipe services cater to specific customer requirements, allowing for tailor-made solutions to meet unique needs. We offer surface passivation and electric polishing as standard surface treatments which can be customized to customer requirements, ensuring a high quality finish on brass casting products.

Losier is a China Brass Sand Casting with Blasting Brass Pipe manufacturer and supplier. We can manufacture any metal parts according to drawings. We are quality conscious and competitive enough to be an attractive supplier to you. We have professional production machines and mature technicians to support us in providing a full range of customized products and services to customers from all over the world.

| Item Name | Customized precision investment casting copper bronze brass castings |

| General Product Application/Service Area | Metal parts solutions for vehicles, agricultural machinery, construction machinery, transportation equipment, valve and pump systems, such as engine brackets, truck chassis brackets, gear boxes, gear boxes, gear covers, shafts, spline shafts, pulleys, flanges, connecting pipes, pipes, hydraulic valves, valve housings, fittings, flanges, wheels, flywheels, oil pump housings, starter housings, coolant pump housings, drive shafts, transmission gears, sprockets, chains, etc. |

| Applicable Materials for Casting |

Brass, bronze, copper; Alloy steel: ZG45, S45C, etc. Stainless steel: CF8, CF8M, G-X6CrNiMo1810, G-X7CrNiNb1189, SUS 304, 304L, 316, 316L. Aluminum or as per customer requirements |

| Applicable Processing Technology | CNC machining/lathe/milling/turning/boring/drilling/tapping/broaching/reaming/grinding/honing, etc. |

| Processing Tolerance | From 0.005mm-0.01mm-0.1mm |

| Machining Surface Quality | Ra 0.8-Ra3.2 according to customer requirements |

| Applicable Heat Treatment | Normalizing, annealing, quenching and tempering, surface hardening, nitriding, carbonitriding, induction hardening |

| Applicable Surface Treatment | Shot peening/sandblasting, polishing, surface passivation, primer, powder coating, ED coating, chromate plating, zinc plate, Dacromet coating, topcoat, |

| Minimum Order Quantity for Mass Production | Brass casting: 100 pieces, or according to customer requirements |

| Delivery Time | Customized precision investment casting copper bronze brass castings 35-45 days |