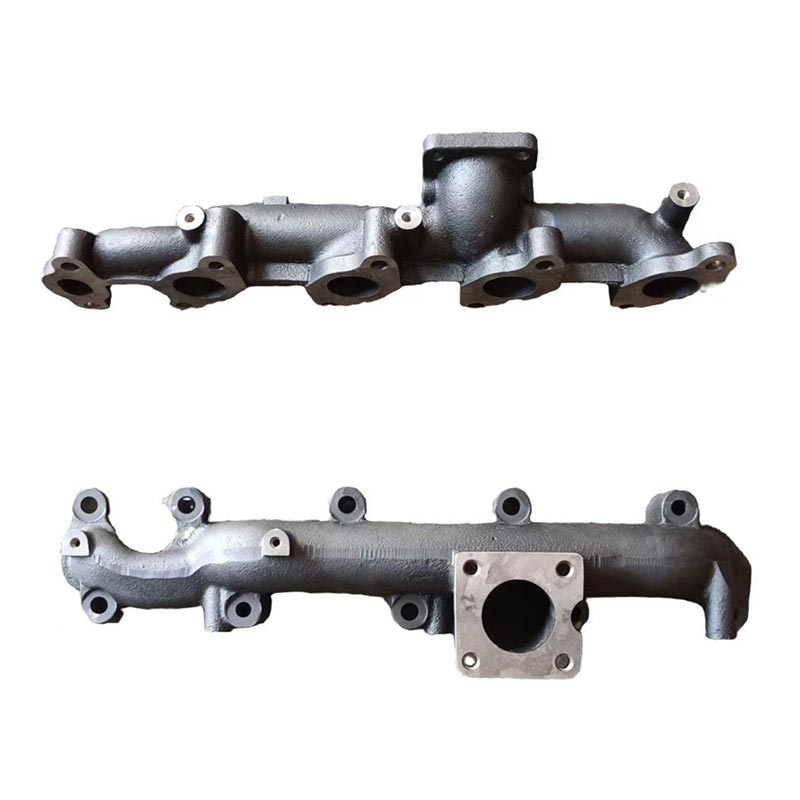

Electric Motor Manifold Wax Castings are precision engineered and durable manufactured to match the fit and function of the original manifold on a specified vehicle. We use our years of industry experience to find the best solutions and achieve optimal performance in specialized applications. Committed to delivering high quality products in compliance with international standards, ensuring reliable performance to meet your industrial needs.

Losier Technology Development Co., Ltd. is a manufacturer and supplier of excellent electric motor manifold wax casting in China. Due to perfect engineering technology and innovative talent, we can solve the manufacturing requirements of the most technically demanding parts. With state-of-the-art machinery, skilled labor, adequate measuring instruments and experienced management, we always provide better quality at the best price. We are committed to your complete satisfaction in terms of products and services.

| Stainless steel | SS201, SS301, SS303, SS304, SS316, SS416, etc. |

| Steel | Low carbon steel, carbon steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90, etc. |

| Copper | C11000, C12000, C36000, etc. |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380, etc. |

| Iron | A36, 45#, 1213, 12L14, 1215, etc. |

| Plastic | ABS, PC, PE, POM, Nylon, PP, Peek, etc. |

| Stainless steel | Polishing, passivation, sandblasting, laser engraving |

| Steel | Galvanizing, black oxide, nickel plating, chrome plating, carburizing, powder coating |

| Aluminum parts | Clear anodizing, color anodizing, sandblasting anodizing, chemical film, brushing, polishing |

| Plastic | Gold plating (ABS), spray painting, brushing (acyl), laser engraving |

| Technology | Investment casting, precision casting, clay sand casting, resin bonded sand casting, resin sand casting, resin coated sand casting, shell mold casting, pre-coated sand casting, silica sol lost wax investment casting, lost foam casting process, water glass casting, soluble glass casting, die casting, hot forging, cold forging, etc. |

| Machining | Drilling, reaming and tapping, CNC turning, CNC milling, EDM wire cutting |

| Process | Mold, casting, deburring, machining, surface treatment, packaging |

| Weight | From 0.1kg-120kg |

| Casting tolerance | CT4-CT8 |

| Machining tolerance | +/-0.02mm |

| Drawing | Required, or provide samples |

| Quality assurance | 100% before shipment QC step inspection |

| File format | PDF, DWG, DXF, IGES, STEP, XT, etc. |

| Application | Glass ribs, glass clamps, vehicle parts, LED housings, support brackets, machine parts, motorcycle spare parts, agricultural machinery parts, engineering machinery parts, engine components, aluminum generator spare parts, engine bushings, automotive radiator accessories, power generation industrial parts, engine blocks, regulator housings, partitions, crane spare parts, general machinery parts, medical equipment components, scaffolding spare parts, defense components, construction spare parts, mining machinery parts, material handling spare parts, LED covers, LED radiators, water pump spare parts, light boxes, water pump spare parts components, general industrial equipment components, baffles, machine bases, automotive suspension spare parts, motor bases, truck parts, etc. |

| Packaging | Cartons / wooden boxes / steel pallets or as per customer requirements |

| Delivery time | Mass production takes 35-45 days |

| Port | Tianjin Port, Tianjin Airport |