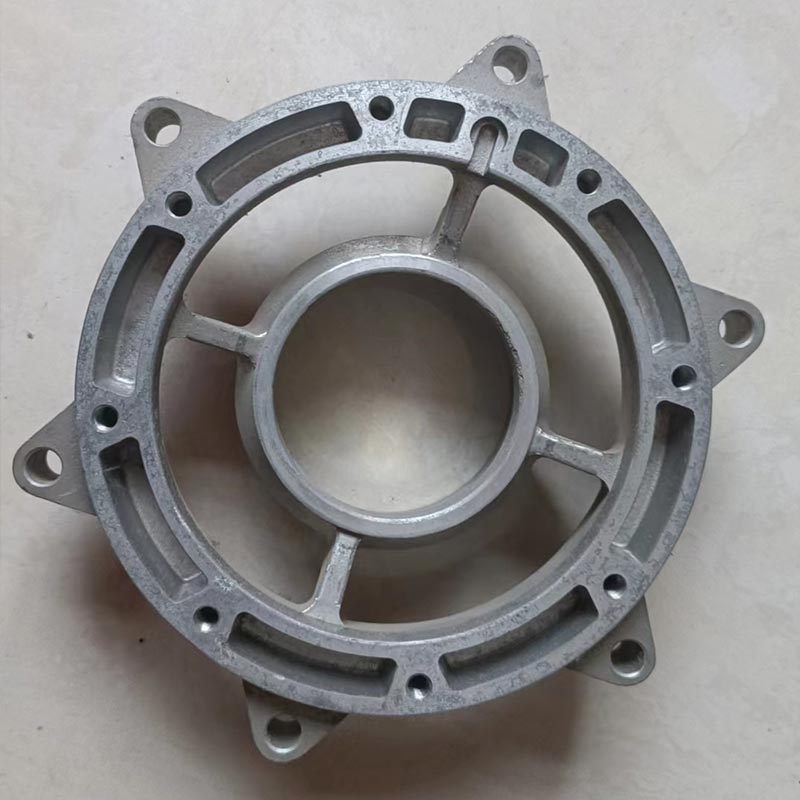

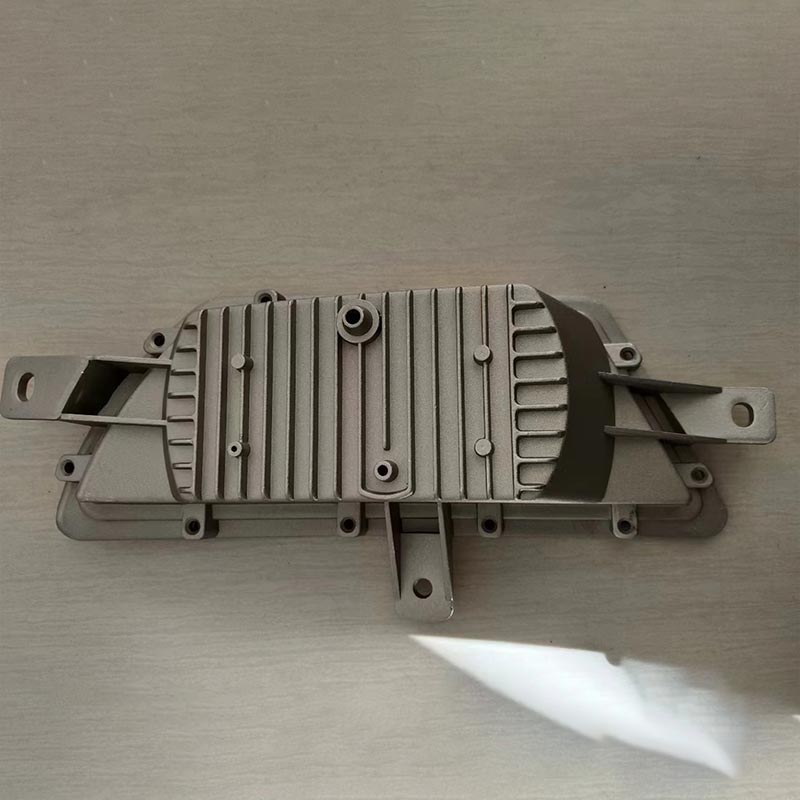

Losier Technology Development Co., Ltd.'s main business: gravity casting aluminum die casting, sand casting, resin sand casting, green sand casting, die casting, gravity casting, shell molding, automatic molding, laser cutting, punching, shearing, bending, pressing, welding metals and materials: carbon steel, stainless steel, aluminum, alloy steel, copper, brass, etc. Processing equipment: laser cutting machine, CNC punching machine, shearing machine, bending machine, welding machine, drilling machine, polishing machine, etc.

Losier has a strong and efficient R&D team that can design and provide gravity aluminum die-casting products based on your ideas and samples. Our specialized gravity aluminum die casting process allows for the creation of custom castings to meet your specific requirements. Whether you require complex geometries, unique shapes, or intricate details, our team of skilled engineers and designers is dedicated to bringing your vision to life.

Gravity die casting (GLD) relies on the natural weight of the molten metal to fill the mold, fundamentally different from high-pressure die casting (HPDC), which relies on external pressure. In the automotive aluminum casting industry, these processes are primarily categorized as follows:

Metal mold gravity casting (Permanent Mold)

Sand core composite gravity casting (Semi-Permanent Mold)

| Equipment Type | Clamping force requirements | Mold life | Applicable Part Sizes |

| Tilt-type gravity casting machine | 50-200 tons | 50, 000-100, 000 pieces | Small and Medium Parts (<20kg) |

| Stationary casting machine | 100-500 tons | 30, 000-80, 000 pieces | Large Parts (≤50kg) |

| Main Process | Sand casting, resin sand casting, green sand casting, die casting, gravity casting, shell molding, automatic molding |

| Material | Ductile iron, gray iron, aluminum, copper, stainless steel, or as per customer's specifications |

| Surface Finish | Sandblasting, polishing, surface passivation, primer, powder coating, ED coating, chromate plating, galvanizing, Dacromet coating, topcoat |

| Casting Dimensions | Cast iron from 2mm to 2000mm / 0.08" to 79" according to customer specifications |

| Casting Weight | Weight range from 0.01kg to 1000kg |

| Processing Technology | We also offer CNC machining, lathes, milling, turning, boring, drilling, tapping, broaching, reaming, grinding, and honing. |

| Processing Tolerances | From 0.005mm to 0.01mm to 0.1mm. |

| Drawing Formats | jpg/.pdf/.dxf/.dwg/.igs/.stp/x_t, etc. |

| Testing Machines | CMMs, digital height gauges, calipers, CMMs, radiographs, roughness testers, hardness testers, etc. |

| Packaging | Plywood pallets, plywood boxes, or custom designs. |

| Services | Our professional export sales team provides enthusiastic and responsive service with years of experience exporting to countries and regions such as the United States, Europe, and Japan. |