As a professional Chinese manufacturer with over 30 years of experience in the foundry industry, Losier Technology specializes in the production of high-precision gravity casting precision aluminum die castings. We provide global customers with aluminum alloy casting solutions featuring complex structures, exceptional strength, and a smooth surface finish, meeting military-grade quality control standards. These products are widely used in new energy vehicles, aerospace, medical devices, and high-end industrial equipment.

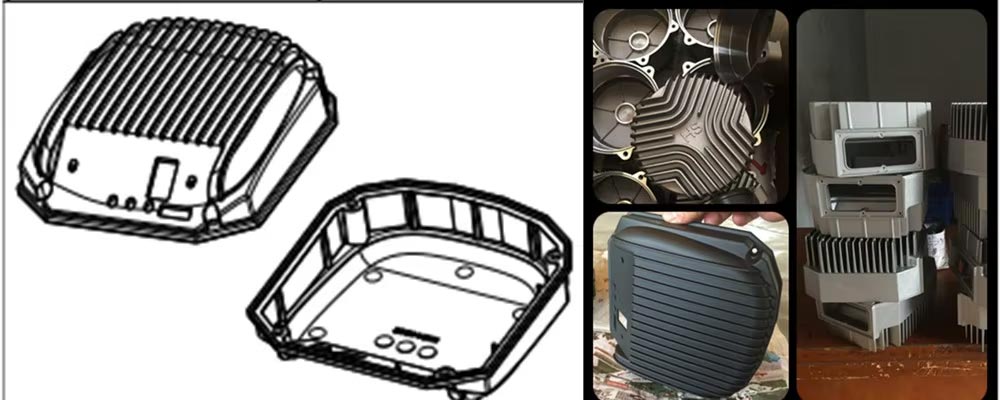

Gravity Casting Precision Aluminum Die Castings produced by custom die casting factories typically require minimal or no machining. Due to the lightweight yet strong nature of aluminum alloys, they have become a popular choice for die casting. Through the aluminum die casting process, more complex designs can be produced for a variety of applications. They already possess a smooth surface and excellent dimensional accuracy. These steel molds can be used multiple times before wear.

Aluminum die casting is a process for gravity casting precision aluminum die castings using aluminum alloy die casting technology. If you are looking for a high-quality aluminum die casting supplier for your project, then look no further as Losier Foundry is the best aluminum foundry manufacturer to choose from and offers services such as aluminum die casting, gravity casting, sand casting, investment casting blank parts, machined and finished parts, surface finishing, CNC machining and many more.

| Features | Technical Specifications | Applications |

| Tensile Strength | 320-380 MPa | Automotive Chassis/Engine Brackets |

| Surface Roughness | Ra ≤ 1.6 μm | Medical Instrument Housings/Optical Equipment |

| Corrosion Resistance | No rust after 1000 hours of salt spray testing | Marine Components/Outdoor Communication Base Stations |

| Thermal Conductivity | 150-180 W/(m·K) | New Energy Battery Cooling Modules |

| Materials | Factory Direct ADC12 A380 High-Quality Aluminum Die Casting |

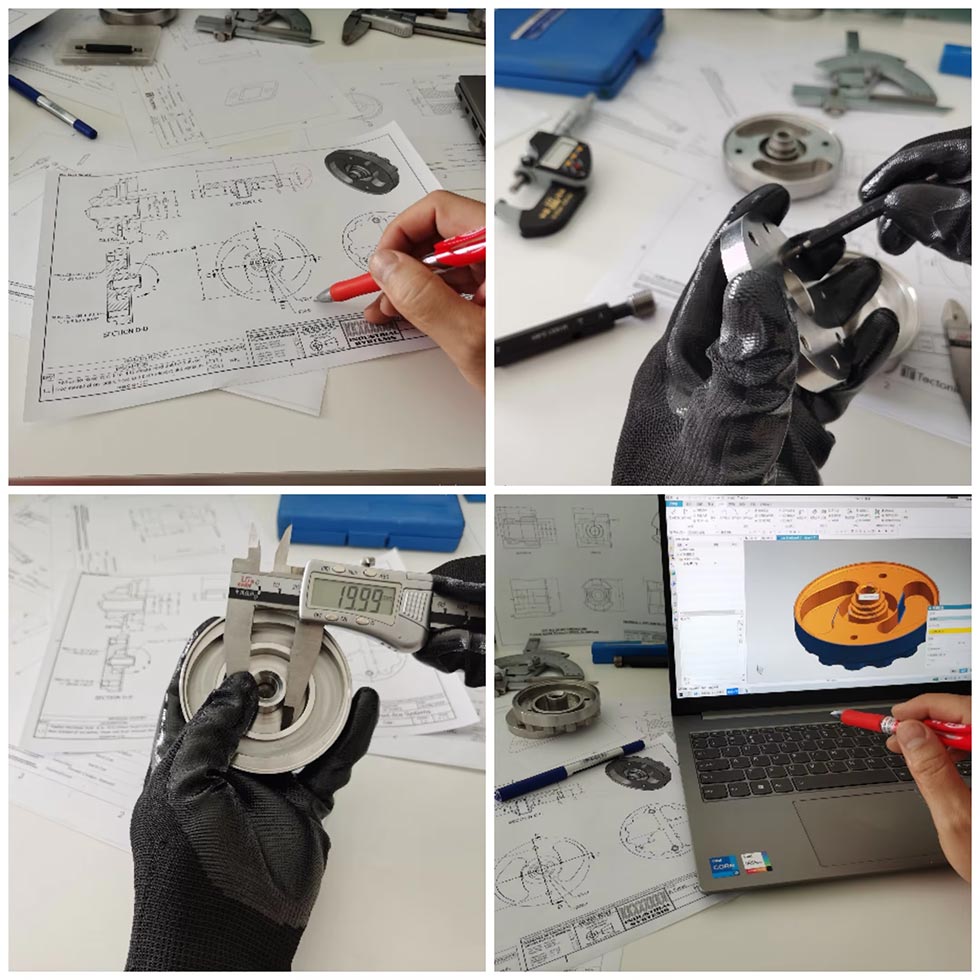

| Processes | Die Casting + CNC Machining |

| Surface Treatments | Sandblasting, Powder Coating, Painting, Anodizing, Polishing, Passivation, E-Coating, Chrome/Nickel Plating... |

| Tolerances | CT4-7 or as required |

| Standards | ASTM、ASME、DIN、JIS、ISO、BS、API、EN、GB |

| Machining | Turning, cutting, milling, grinding, and drilling |

| OEM/ODM Part Range | For automotive parts, electronic components, furniture parts, home appliances, and other industrial applications |

| Packaging | Cartons are then placed on wooden crates or as per your requirements. |

(1) ODM and OEM services based on your drawings, specifications, and/or samples

(2) Small quantities and mixed items are also available

(3) High precision, new technology, and competitive casting and machining prices

(4) Advanced casting machines available

(5) Comprehensive facilities for CNC machining, turning, milling, tapping, drilling, polishing, punching, and more

(6) Competitive pricing, excellent service, and good delivery times.

Supplier Direct: Manager Zhang 17731770068

Email: hongyu@shijiacasting.com (Submit drawings to receive an instant technical proposal)

Website: www.shijiacasting.com

Address: Botou City, Hebei Province, China (adjacent to Beijing and Tianjin, with global logistics coverage)