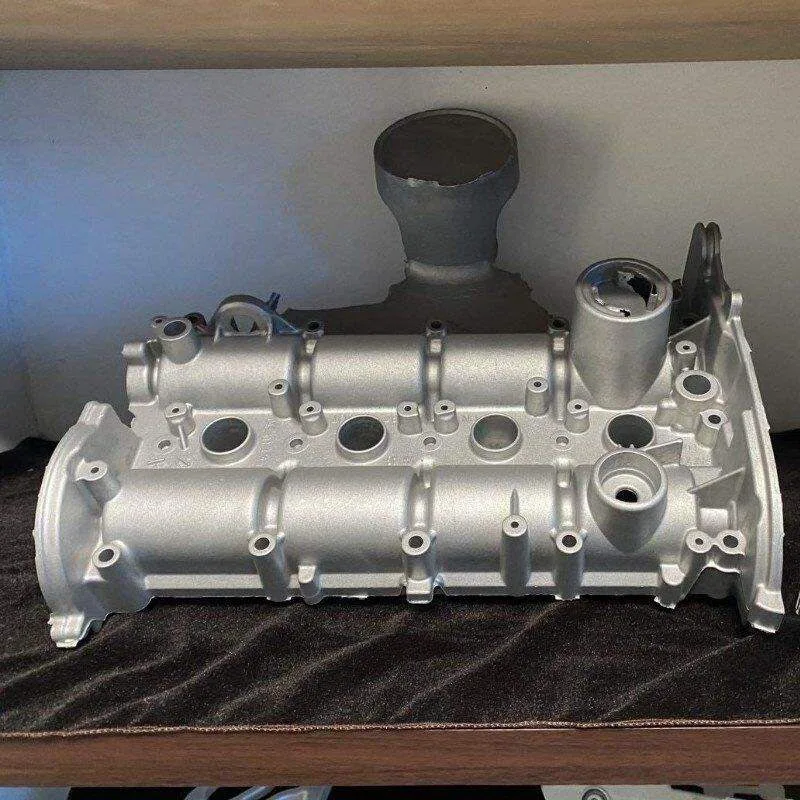

Low-Pressure aluminum alloy castings require high precision to meet product assembly requirements. Therefore, our company is equipped with 24 CNC machining centers and over 22 CNC milling and lathes. Our CNC machines can achieve a minimum accuracy of 0.0005.

Losier Technology Development Co., Ltd. is a manufacturer and supplier of low-pressure aluminum alloy castings with many years of experience. We provide customers with high-value-added, high-quality products and services through comprehensive, one-stop professional solutions, from product design and development, mold manufacturing, die-casting, deep processing, surface treatment, and delivery. The entire processing range includes die-casting, lost wax casting, sand casting, CNC machining, milling, grinding, laser cutting, welding, surface treatment, and more.

We are confident in providing you with the highest quality service at competitive prices. We are committed to the principles of mutual benefit and long-term cooperation. We sincerely hope to establish business relationships with our customers and work together for common development!

| Materials | Aluminum, stainless steel, brass, steel, plastic, nylon, titanium |

| Tolerance Standards | Conventional parts ± 0.05 mm, precision parts ± 0.02 mm |

| Surface Roughness | Ra 1.6 μm (fine grinding), Ra 3.2 μm (rough finishing) |

| Surface Treatment | Zinc plating, nickel plating, chromate plating, anodizing |

| Processing Technology | Milling, turning, drilling, boring, grinding, and multi-axis machining |

| Performance Parameters | Conductivity, corrosion resistance, and high-temperature resistance |

| Applications | Applications: motorcycles, automotive, robotics, aerospace, drones, medical, and communications |

| Production Capabilities | 25, 000, 000 pieces/order, delivery within 10-25 days |

| Customization Capabilities | Customized processing according to customer requirements |

| Surface treatment | Suitable Materials | Description |

| Anodizing | Aluminum, titanium, magnesium, and their alloys | Excellent hardness, wear resistance, corrosion resistance, and insulation properties. Can be dyed. Used in construction, automotive, and other parts. |

| Sandblasting | Metals and some non-metals, such as glass and ceramics | Uses compressed air to clean surfaces with abrasive jets to achieve a smooth and clean surface. |

| Galvanizing | Steel | Rust-proof: Hot-dip galvanizing offers a thick and corrosion-resistant coating for construction and other applications; electroplating offers a superior appearance for parts. |

| Laser Engraving | Metals and various non-metals, such as wood and plastics | High precision, fast processing, and customizability. |

| Erosion Oil Filling | Various metals | Rust-proof: Used for short-term rust prevention of metal products. |

| Painting | All materials | Protective and decorative: Available in a variety of colors and easy to apply. |

| PVD | Metals and some ceramics and glass | Improves hardness, wear resistance, corrosion resistance, and decorative properties. |

| Electrophoresis | Metals, such as steel and aluminum alloys | Strong adhesion, corrosion resistance, and environmentally friendly. |

| Grinding | Metals and high-hardness non-metals, such as hardened steel and ceramics | Produces high precision and smoothness, a finishing method. |

| Polishing | Metals and some non-metals, such as plastics and glass | Reduces roughness and produces a bright, flat surface. |

| Nickel Plating | Steel, copper, and their alloys | Corrosion resistance, wear resistance, and gloss: Available in dark nickel and bright nickel. Used in electronics and hardware. |

| Chromium Plating | Steel, copper alloys, and aluminum alloys | High hardness, wear resistance, and gloss: Available in hard chrome and decorative chrome. |

| Phosphating | Steel, zinc, aluminum, and their alloys | Used for rust prevention and pre-painting. |

| Blackening (Bluing) | Steel | Improves corrosion and wear resistance. |

| Powder Coating | Metals and some heat-resistant non-metals | Environmentally friendly: Excellent coating performance and a variety of colors. |