When it comes to delivering strength, precision, and long-term value, precision-cast aluminum parts are taking center stage in industries that demand high-quality components. But what’s behind the buzz—and are these parts the right fit for your next project?

Precision casting aluminum parts are created using advanced casting methods like gravity casting, permanent die casting, and metal casting. These techniques allow for the production of complex shapes with tight tolerances and consistent surface finishes. Whether you're working with Aluminum A356, ZL102, ZL104, or ZL107, you’ll get components that are strong, lightweight, and corrosion-resistant.

· Save Time on Machining: Thanks to high casting accuracy, less machining is required post-production.

· Reduce Downtime: High durability and precise fit mean fewer replacements and less maintenance.

· Boost Product Appeal: Sleek finishes and refined details give your final products a more professional look.

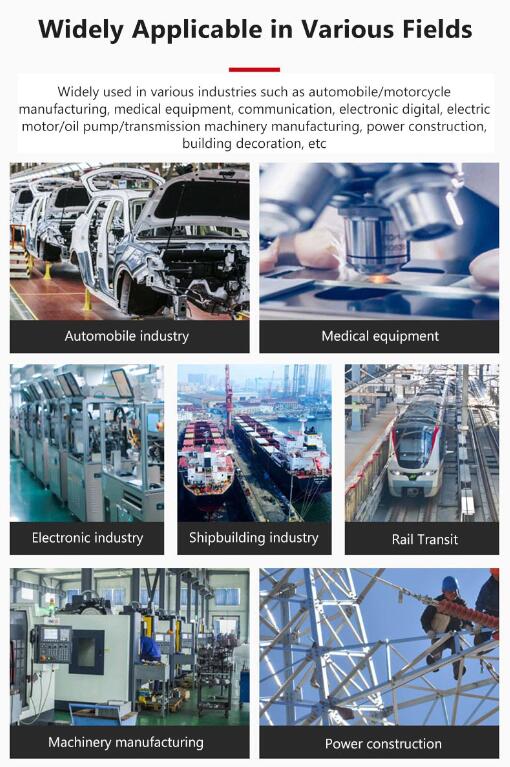

These aluminum components are a go-to for many industries:

1. Medical Devices: For example, aluminum housings and brackets are commonly used in surgical instruments and diagnostic machines due to their light weight and corrosion resistance.

2. Automotive Parts: They're ideal for engine blocks, transmission cases, and suspension components—offering strength without adding excessive weight, which boosts fuel efficiency.

3. Aerospace Components: From aircraft seat frames to cabin fittings, precision aluminum parts help reduce overall weight while meeting strict safety standards.

4. Consumer Electronics: Think of sleek, durable laptop casings and internal heat sinks—both benefit from precision-cast aluminum.

5. Home Appliances: Common in parts like washing machine drums and air conditioner housings, where strength and rust resistance are key.

6. Furniture and Industrial Equipment: Frequently used in adjustable joints and support frames for their clean appearance and stability.

From high-tech equipment to everyday consumer goods, their adaptability makes them an essential part of many manufacturing ecosystems.

We back our components with comprehensive testing tools: spectrometers, coordinate measuring machines (CMMs), calipers, micrometers, hardness meters, and more. You can be confident you're getting parts that meet the highest standards.

Cangzhou Losier Technology Development Co., Ltd., founded in 1986, has decades of experience in casting, machining, and large machine tool support. Our range includes aluminum castings, iron castings, steel castings, die-cast aluminum and zinc alloy parts, and more. Learn more about our capabilities at https://www.shijiacasting.com. For inquiries, contact us directly at hongyu@shijiacasting.com.