Cangzhou Losier Technology Development Co., Ltd. specializes in the processing and sales of aluminum castings, copper castings, iron castings, and die-cast parts. With skilled quality control personnel and workers, we guarantee you a choice in both style and quality.

In modern manufacturing, die-casting, with its high efficiency and precision, is widely used in a variety of industries, including automotive, electronics, and home appliances. Today, we'll take you behind the scenes of our die-casting facility to learn about this industry.

What is die-casting?

Die-casting is a process in which molten metal is poured into a mold under high pressure and then cooled and formed. Its key features are a high degree of automation, short production cycles, and high-precision finished products. It is particularly suitable for the mass production of small, precision parts.

Common die-cast metal materials include aluminum alloys, zinc alloys, and magnesium alloys. Choosing the right alloy can significantly improve product performance in different applications. For example, aluminum alloys are widely used in automotive engines, heat exchangers, and other components due to their excellent thermal conductivity and corrosion resistance.

Die Casting Process

In a die casting plant, every step is crucial. The entire die casting process primarily includes the following steps:

Mold Design and Manufacturing: The mold is key to the die casting process, determining the shape and precision of the final product. When designing the mold, factors such as material flowability, cooling efficiency, and ease of demolding after molding should be considered.

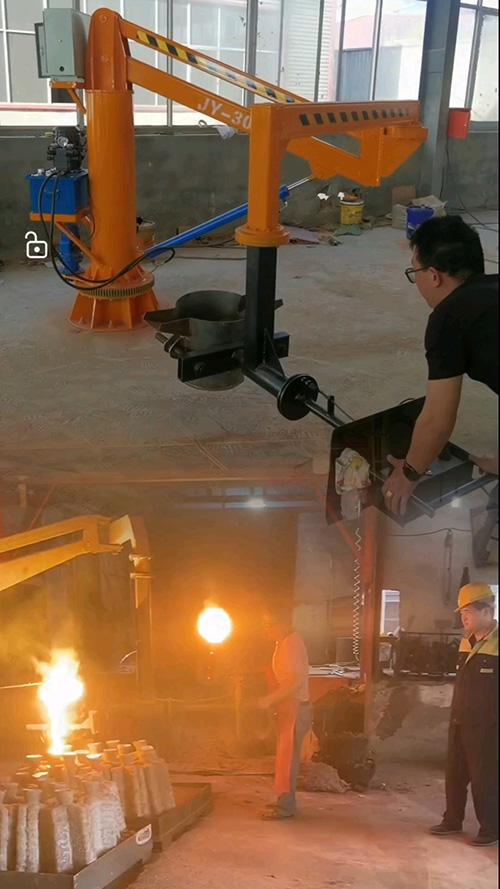

Melting Metal: In a high-temperature furnace, metals such as aluminum alloys or zinc alloys are heated to a molten state. Temperature control is crucial to die casting quality; excessively high or low temperatures can affect the precision and appearance of the product.

Injection Molding: Molten metal is injected into a mold under high pressure, rapidly cooled, and formed. This process typically takes from a few seconds to tens of seconds, depending on the type of metal and the complexity of the mold.

Demolding and Cleaning: The finished casting is removed from the mold and undergoes demolding, deburring, and other processes to remove excess metal and achieve the final product shape.

Inspection and Quality Control: After production, die castings undergo rigorous testing, including dimensional accuracy, surface finish, and material strength. High-precision testing equipment, such as 3D measuring machines and film thickness gauges, ensures that product quality meets high standards.

The Core Competitiveness of Die-Casting Plants

In addition to sophisticated craftsmanship, the competitiveness of die-casting plants is also reflected in the following aspects:

Technical Strength: With the advancement of manufacturing technology, die-casting processes are gradually moving towards intelligent and automated processes. Modern die-casting plants generally use high-end digital control systems, which can precisely control every step of the process, thereby ensuring product consistency and high quality.

Equipment Advantages: A high-quality die-casting plant will have large-tonnage die-casting machines and advanced testing equipment to handle a variety of complex and precise casting tasks. For example, zinc alloy and aluminum alloy die-casting machines ranging from 80 to 1,000 tons can handle castings of various specifications to meet diverse customer needs.

Quality Control: Die-casting plants maintain particularly strict quality control. Many plants have implemented a full inspection system, using standardized and regularized processes to ensure that every product meets technical requirements. Comprehensive testing equipment and management systems enhance product consistency and reliability.

Industry Applications and Future Trends

With the rapid development of industries such as new energy and intelligent manufacturing, the application of die-casting technology is becoming increasingly widespread. Demand for die-cast products is particularly increasing in areas such as new energy vehicle parts, energy storage equipment, and household hardware.

In the future, the die-casting industry will develop in the following directions:

Green and environmentally friendly: With increasing environmental protection requirements, the die-casting industry will place greater emphasis on energy conservation and emission reduction, promoting the application of green production processes.

High efficiency and intelligence: Future die-casting plants will place greater emphasis on automated and intelligent production, leveraging AI and big data analytics to improve production efficiency and product quality.

High precision and customization: As customer demands for product precision and personalization continue to increase, die-casting plants will increase their investment in precision manufacturing to meet the diverse market demands.

As a vital component of modern manufacturing, die-casting plants ensure the production of a wide range of high-quality castings through sophisticated processes and strict quality control. With continuous technological advancement, the die-casting industry will usher in more development opportunities and become a vital force supporting the development of modern industry.

Behind every precision die-casting is the crystallization of technology and the unremitting efforts of the enterprise. As the manufacturing industry continues to innovate, die-casting will continue to provide efficient and reliable parts for a wide range of industries, contributing further to global industrial development.

You're also welcome to visit our factory.