Losier specializes in providing high-quality precision die-cast aluminum parts processing solutions to meet the diverse needs of our global customers. Our factory is equipped with advanced molds, die-casting machines, and CNC machinery, including cutting-edge machining centers, lathes, and milling machines. We also utilize state-of-the-art inspection tools to ensure top-notch quality in every product.

We are a leading manufacturer in China, manufacturing and selling precision die-cast aluminum parts for many years! Quality is our top priority in everything we do at Losier Technology Development Co., Ltd. We adhere to a rigorous quality control process, meticulously monitoring every stage of production, from material sourcing to final inspection, to ensure the highest levels of precision and reliability.

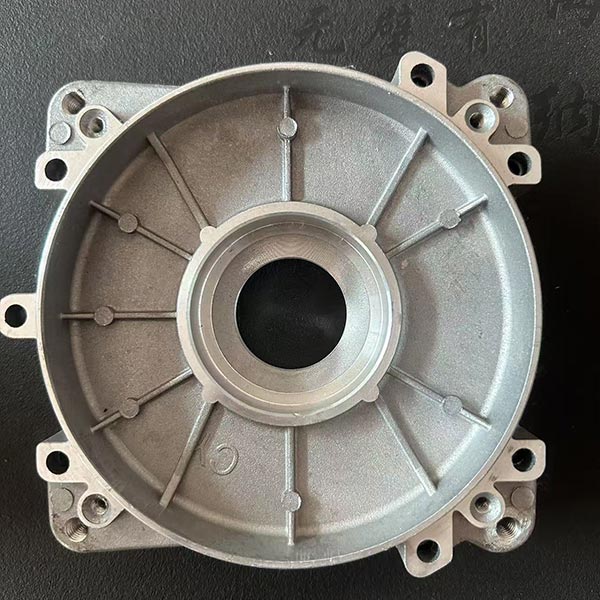

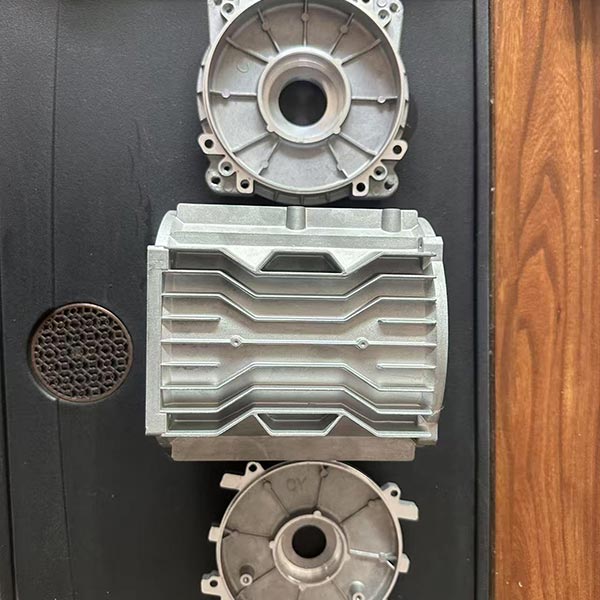

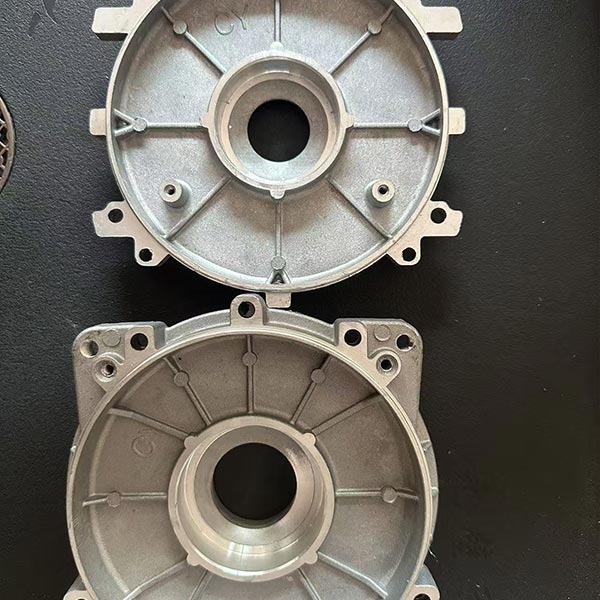

Precision die-cast aluminum parts are high-precision metal components created using high-pressure die-casting technology. Molten aluminum alloy is injected into a precision mold cavity at high speed and pressure, then rapidly cooled and solidified. This process is particularly suitable for the high-volume production of aluminum alloy parts with complex geometries, thin-walled features, stringent dimensional requirements, and excellent surface quality.

| Stainless Steel | SS201, SS301, SS303, SS304, SS316, SS416, etc. |

| Steel | Mild carbon steel, carbon steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc. |

| Copper/Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90, C11000, C12000, C36000, etc. |

| Aluminum Alloy | ADC12, ADC10, A360, A380, A356, 6061, 6063 |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380, etc. |

| Iron | A36, 45#, 1213, 12L14, 1215, etc. |

| Zinc Alloy | ZA3#, ZA5#, ZA8# |

| Processing Technology | Drawing → Mold Making → Die Casting → Rough Machining → CNC Machining → Surface Treatment → Product Inspection → Packaging → Delivery |

| Tolerances | ± 0.02mm |

| Surface Treatment | Electroplating, Chrome Plating, Zinc Plating, Nickel Plating, Electrophoresis, Anodizing, Polishing, Sandblasting, Passivation, Powder Coating, Painting, etc. |

| Quality Assurance | Two Years |

| Inspection |

1. In-house casting: 100% inspection of critical dimensions; 100%

inspection of appearance. 2. Third-party inspection available upon request. |

| Primarily Testing Facilities | Three-dimensional measuring machine (CMM), X-ray defect detector, salt spray test chamber, dynamic balance detector, pneumatic testing |

| Features and Benefits |

1. High processing precision, with a flatness within 0.1 mm. 2. High strength, non-deformable, and excellent electrical and thermal conductivity. 3. Highly polished appearance, with a surface roughness of Ra1.6 after processing. 4. High processing precision, seamless assembly structure. 5. No particles, spots, or paint peeling. 6. Smooth appearance and corrosion resistance. 7. Passed 20, 000 abrasion resistance test. 8. Passed salt spray test for 96 hours. 9. Passed coating adhesion test and anti-scratch test. 10. Passed adhesion cross-cut test and 3m glue test. 11. Passed film thickness test. |

| Applications | 3C industry, lighting and decoration, electrical appliances, automotive parts, furniture accessories, power tools, medical equipment, intelligent automation equipment, and other metal castings. |

We specialize in providing customers with one-stop solutions from product design optimization (DFM), mold development, precision die-casting production, precision machining (CNC), strict quality control, and surface treatment. With advanced production equipment, extensive process technology accumulation and a strict quality management system, we are committed to producing high-quality precision die-cast aluminum parts with accurate dimensions, reliable performance and good consistency. We help customers solve multiple challenges such as lightweighting, complex structures, and cost-effectiveness, and enhance the core competitiveness of their products.