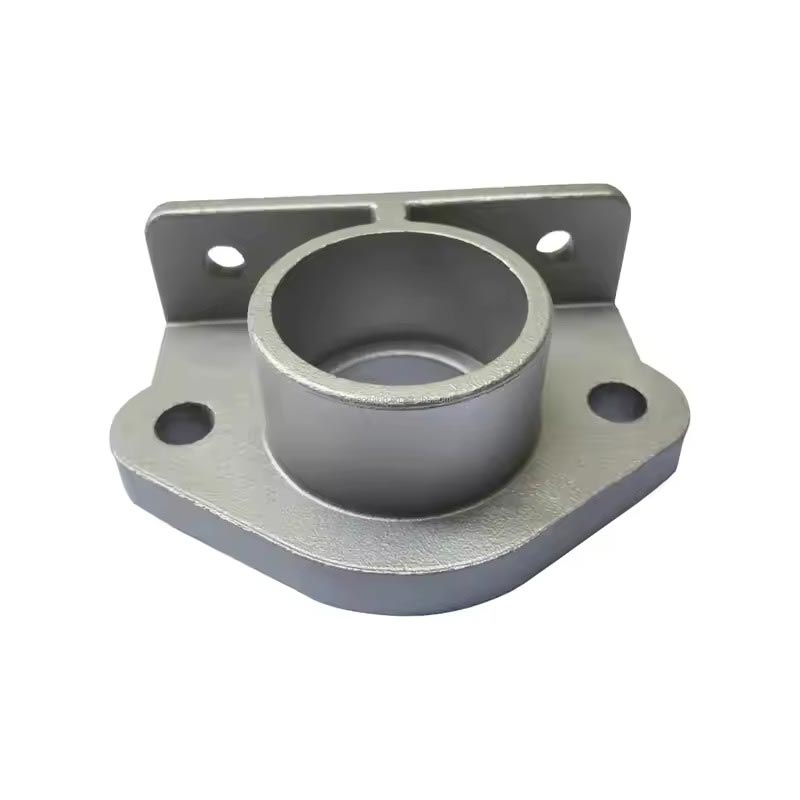

Our company strictly inspects the raw materials of stainless steel 316 investment casting to ensure that our product materials are always of high quality. Experienced engineers use professional design software to optimize product structure and complete product design, control molten steel temperature and other production processes to ensure that our products have precise dimensions and smooth and beautiful appearance.

Losier Technology Development Co., Ltd. is located in Hebei, China and is a leading manufacturer and supplier of stainless steel 316 investment casting. Always taking quality as the key standard, the company has strong R&D capabilities and develops many new products every year. It has a group of professional and experienced engineers who are responsible for product design, drawing drafting, modification, product quality control, and can meet all customer requirements.

| Material | Carbon steel, alloy steel, stainless steel, aluminum alloy, copper, etc. |

| Process | Investment casting + CNC machining |

| Casting dimension tolerance | CT7 |

| Casting surface roughness | Ra 12.5 um |

| Casting weight range | 0.1-90 kg |

| Casting size | Maximum linear size: 1200 mm, maximum diameter size: 600 mm |

| Machining accuracy | Positioning accuracy 0.008 mm, representative position. Accuracy 0.006 mm |

| Machining surface roughness | Ra0.8 ~ 6.3 um |

| Maximum spindle travel | 1900 mm x 850 mm x 700 mm |

| Maximum turning diameter | 830 mm |

| Material standard | GB, ASTM, AISI, DIN, BS, JIS, NF, AS, AAR |

| Surface treatment | KTL (electronic coating), galvanizing, mirror polishing, sandblasting, pickling, black oxide, painting, hot dip galvanizing, powder coating, nickel plating. |

| Services provided | OEM & ODM |

| Quality control | 0 defect, 100% inspection before packaging |

| Application | Trains and railways, cars and trucks, construction machinery, forklifts, agricultural machinery, marine parts, oil machinery, construction, valves and pumps, motors, hardware, power equipment, etc. |

| Keywords | Investment casting, sand casting, precision casting, lost wax casting, water glass casting, silica sol casting, die casting |