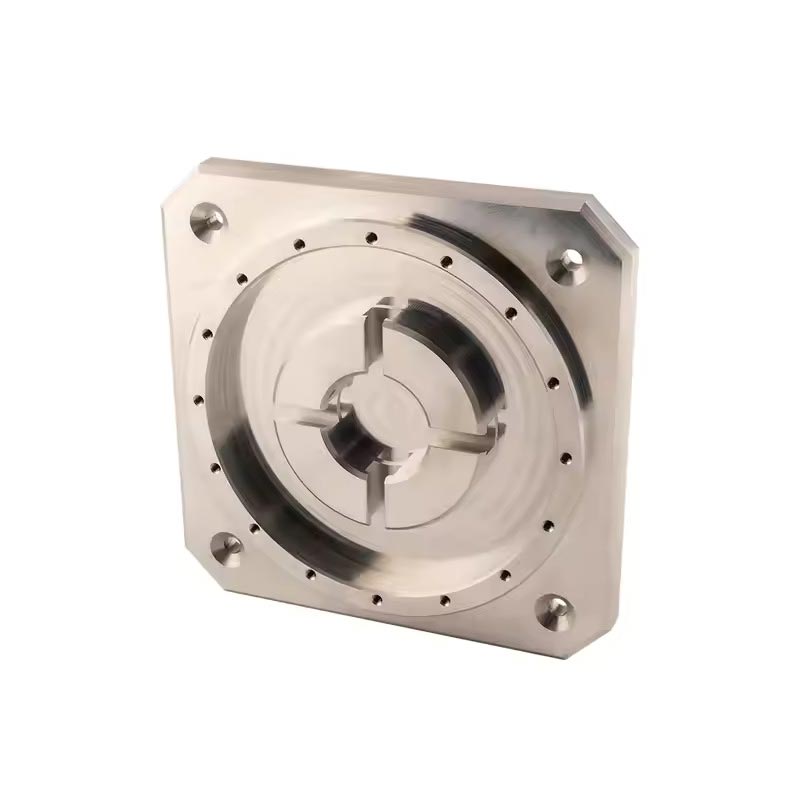

To cast stainless steel investment casting machinery part, we first make a model of the desired part using materials such as wax. We then pour the liquid metal into the mold. After cooling, the shell is removed to reveal the metal casting. Finally, the casting goes through various processes such as cutting, grinding and polishing to achieve the final desired shape and surface finish.

Losier is a China manufacturer with rich production experience in producing excellent stainless steel investment casting machinery parts. To ensure the integrity and precision of the production of stainless steel precision casting machinery parts, strict quality control measures are implemented throughout the workshop. The factory is headquartered in Hebei, China, with a modern production base and advanced production equipment. We are committed to providing high-quality machinery parts and providing excellent services to global customers.

| Item | Value |

| Product Name | High Precision Investment Casting Parts/Lost Wax Casting Parts |

| Material | Stainless Steel, Carbon Steel, Alloy Steel, Titanium Alloy or Customized |

| Brand Name | Customized |

| Design Support | PDF, 3D, step file or sample are all accepted. |

| Quality Control | One by one complete 100% before packing |

| Surface Treatment | Electronic coating, zinc, polishing, sandblasting, galvanizing, powder coating |

| Application | Automobile manufacturing, lighting photography, aerospace, cosmetics, food and chemical industry, medical equipment, new energy, heavy machinery and construction industry, etc. |

| Process | Mold + wax injection + dewaxing + casting + machining (if needed) + surface treatment |

| Machining | Drilling, reaming, tapping, CNC lathe, CNC machining center and milling, EDM, etc. |

| Service | OEM/ODM and solutions, small orders are welcome. |

| Tolerance | P690-D1 or 0.02mm |

| Packaging | Carton, plastic bag, wooden or iron/steel pallet or as per customer requirements |

| Dimensions | 2mm-620mm |

| Delivery Time | 3-5 days for samples, 20-35 days for bulk orders. |