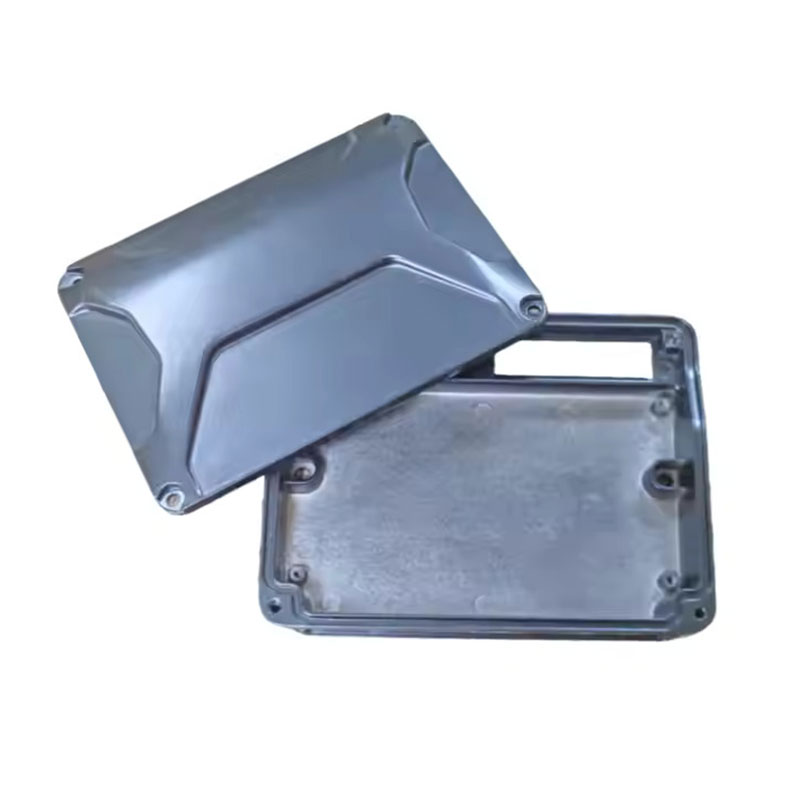

Our zinc alloy die casting products undergo die casting and machining processes to ensure high precision and high quality of the final product. A range of surface treatments are available based on customer needs, including powder coating, painting, sandblasting and anodizing, allowing customers to choose a surface treatment that suits their needs, such as a specific color required by the customer.

Losier is a China manufacturer with rich production experience in producing Zinc Alloy Die Casting. In order to meet the different mechanical and functional requirements of customers, we produce various metal products for customers based on different billet solutions and technologies. These billet solutions and technologies include zinc alloy die casting, iron casting, copper casting, steel casting, stainless steel casting, aluminum casting and forging processes.

| Quote | According to your drawings (size, material, thickness, processing content and required technology, etc.) |

| Available Materials | Brass, stainless steel, copper, aluminum alloy, zinc alloy, etc. |

| More Treatments | CNC machining, injection molding, stamping, die casting, welding, forging, silicone rubber, mold making, etc. |

| Surface Treatment | Powder coating, anodizing, brushing, polishing, electroplating, PVD coating, hot dip galvanizing, e-coating, tin plating, nickel plating, chrome plating, Dacromet, enamel coating, etc. |

| OEM | Screen printing, engraving, laser printing, cutting production, customized packaging boxes, etc. |

| Applications | Various automobiles, machinery, home appliances, electronic products, electrical appliances, stationery, computers, power switches, micro switches, construction, commodities and A/V equipment, hardware and plastic molds, sports equipment and gifts, etc. |

| Manufacturing Types | Precision machining, CNC milling, CNC lathe turning, tapping, drilling, grinding, Wie EDM, stamping, deep drawing, CNC stamping, laser cutting, CNC bending, die casting, welding, etc. |

| Industries Served | Aerospace, automotive, agriculture, construction, electrical, electronics, home appliances, medical, marine, machinery, furniture, food, lighting, telecommunications, etc. |

| File Formats | Solidworks, professional/engineer, automatic CAD, PDF, JPG, DXF, IGS, STEP |

| QC | 100% strict inspection for every process |

| One-Stop Service | Custom design, manufacturing, assembly and delivery |