As a leading precision manufacturer in China, Losier has been deeply involved in the casting and precision machining fields since its establishment in 1986, providing high-quality parts solutions to over 2000 customers worldwide. Losier offers a one-stop service from design, prototyping, machining, assembly to surface treatment, making us a trustworthy Aluminum CNC Machining Part Supplier & Factory.

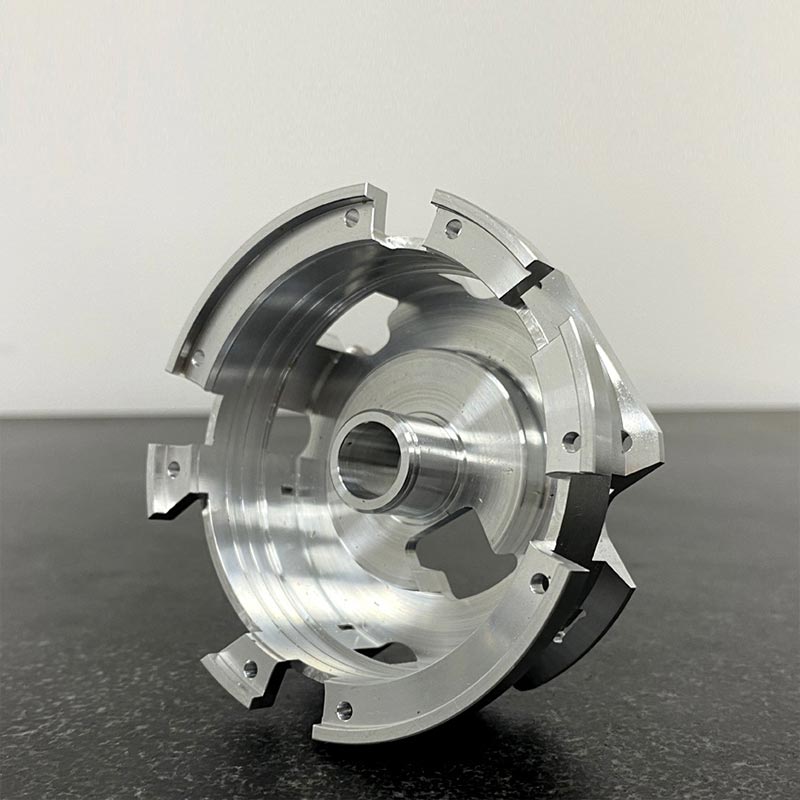

Aluminum CNC Machining Parts refer to functional parts made by machining aluminum and aluminum alloys using CNC turning, CNC milling, and five-axis machining to achieve high precision, high strength, and high surface quality.

Core advantages include:

1. Ultra-lightweight and optimized structure: Aluminum alloys have a low density, only one-third that of steel, significantly reducing equipment weight. Suitable for:

Aerospace

Automotive lightweighting

Portability of medical equipment

Weight reduction in industrial automation equipment

2. Excellent heat dissipation performance:

Aluminum has excellent thermal conductivity, making it an ideal material for heat sink housings, power module housings, instrument chassis, and other components.

3. High strength and easy machining:

High-strength aluminum combined with CNC precision machining can achieve high precision requirements of ±0.001mm.

4. High-end appearance and various surface treatments:

Anodizing, sandblasting, polishing, electroplating, etc., enhance appearance quality, wear resistance, and corrosion resistance.

Therefore, Aluminum CNC Machining Parts are widely used in: Medical Devices (Stents, Housings, Surgical Instruments) Automotive Parts (Engine Accessories, Bushings, Adapters, Brackets) Aerospace (Structural Components, Lightweight Frames) Electronic Equipment (Radiators, Housings, Connectors) Mechanical Manufacturing (Jigs, Fixtures, Structural Blocks)

Losier can customize production based on customer drawings, samples, 3D data, and concept models.

Losier is a supplier with dual capabilities in casting and precision machining, possessing CNC machining centers, 5-axis lathes, mill-turning machines, and coordinate measuring machines (CMMs) to provide customers with aluminum machining solutions that meet stringent standards.

Our Advantages:

1. High Precision: ±0.001mm ~ ±0.005mm

Meets the stringent dimensional requirements of industries such as aerospace, medical, and automotive.

2. Multiple Process Combinations for Complex Structure Machining

CNC Turning

CNC Milling

3-Axis, 4-Axis, and 5-Axis Machining

Mill-Turning Machines

3D Printing Rapid Prototyping

3. One-Stop Service

Complete process from material procurement → machining → heat treatment → surface treatment → assembly → packaging.

4. Support for Small Batch, Highly Mixed Orders

Easily handles orders from a single sample to thousands of pieces.

5. Wide range of material options

Including: aluminum, aluminum alloys, stainless steel, steel, copper, brass, titanium, plastics, and custom materials.

| Product Name | Custom made aluminum casting CNC machining milling turning aluminum parts service |

| Material | Metal: Albuloys 5052,2024,6061,6063,7075,6082, etc. |

| Surface Treatment | Sandblasting and anodic oxidation, wire drawing, chrome plating, polishing, powder spraying, etc. |

| Tolerance | +/-0.01mm, 100% QC quality check before packaging. |

| Testing Equipment | CMM, tool microscope, multi-articular arm, automatic altiometer, manual altimeter, micrometer, marble platform, roughness measurement |

| Machining | CNC turning, CNC milling, laser etch marks |

| File Format | Solid Works、Pro/Engineer、AutoCAD(DXF、DWG)、3D(STEP、STP、IGS、XT)、PDF、TIF、etc.。 |

| Service Items | Provide product design, production and technical services, mold development and processing, etc. |

| Completion | Description | Materials | Purpose | ||

| Anodizing | Corrosion-resistant hard coating | Aluminum | Corrosion protection, decoration | ||

| Sandblasting | Matte texture controlled by abrasive blasting | Aluminum, Steel, Brass | Pretreatment, decorative | ||

| Electroplating | Metallic coating for protection or conductivity | Steel, Aluminum, Brass | Corrosion resistance, enhanced appearance | ||

| Polishing | Smooth or mirror finish | Aluminum, Steel, Brass | Aesthetics, reduced roughness | ||

| Powder coating | Durable, uniform protective layer | Aluminum, Steel, Brass | Abrasion resistance, colored finish | ||

| Zinc plating | Rust-resistant zinc coating | Steel | Outdoor or structural use |

Professional: As CNC machining manufacturers, engineers and technicians have more than 15 years of custom machining experience. We can analyze and carefully grasp the important areas of custom machining parts

Design ability: Scan and process parts according to samples without CAD drawings.

Qualified quality: Parts are inspected by professional quality inspectors 100D measuring instrument 3%

Confidentiality: Sign a confidentiality agreement to protect the buyer's design.

Material: Aluminum 2024/ 5052/ 6061/ 6063/ 7075, stainless steel 303/ 304/ 316, carbon fiber, titanium, POM, nylon, ABS, PEEK, PTFE, polycarbonate, polyethylene, PVC, PMMA, PET, polypropylene.

Losier Technology Development Co., Ltd. adheres to the corporate tenet of "Quality as the Foundation, Innovation as the Core, and Service as the Lifeblood," and is committed to providing internationally high-quality aluminum CNC machined parts to help global customers enhance their product competitiveness.

Engineers and purchasing managers are welcome to send drawings to our technical department. We will provide free process analysis and a quotation.

Contact Information:

Manager Zhang: 17731770068

Email: Available upon request

Global customers are welcome to visit our factory and discuss mutual development!