Our carbon steel CNC machining parts are strictly controlled. Each product has its own process card and process drawing. Each size of product must be tested one by one after the production is completed. We carefully implement various regulations in the management details to fully guarantee the quality of carbon steel CNC machining parts and customer satisfaction. We provide a complete service, including a full range of molds, products and material/color selection.

Losier Technology Development Co., Ltd. is a manufacturer and supplier of custom carbon steel CNC machining parts, all carbon steel CNC machined parts of our company have no sharp edges. All dimensions are controlled according to your drawings. Each product will be fully inspected and carefully packed to prevent bumps and rust during transportation.

Our quality inspection procedures are very strict. Self-inspection must be carried out during the production process, and we have flow inspectors and professional inspectors. At the same time, we aim to provide precise one-stop service solutions and the fastest business support for global industrial users to develop, produce and manufacture tens of thousands of custom industrial parts.

| Projects | Stainless steel CNC machining parts |

| Services | OEM/ODM or custom production |

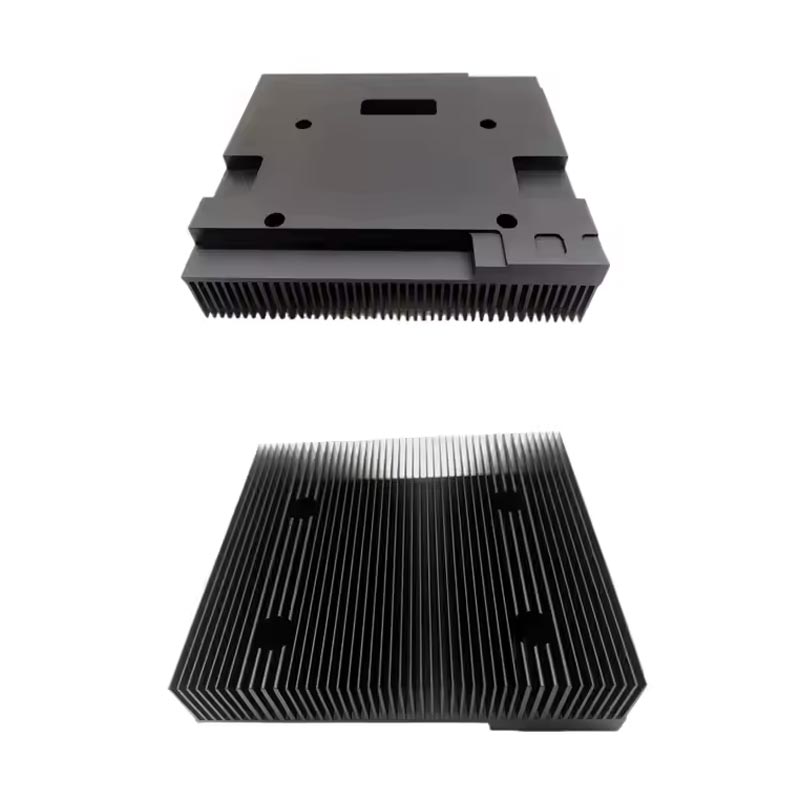

| Process technologies | Precision CNC machining + surface treatment |

| Materials we can cast | Gray cast iron, ductile iron, pig iron, carbon steel, stainless steel, alloy steel, aluminum alloy, aluminum, A380, aluminum 6061, zinc alloy, copper, brass, bronze CuZn38, H62, etc. |

| Dimensions | Customized as customer drawings |

| Weight ranges | 0.02-500 kg |

| Applications and services | Metal parts solutions for vehicles, agricultural machinery, construction machinery, transportation equipment, valve and pump systems, etc., as engine brackets, truck chassis brackets, gear boxes, gear covers, pulleys, flanges, connecting pipes, pipes, hydraulic valves, valve housings, fittings, flanges, wheels, flywheels, oil pump housings, starter housings, coolant pump housings, drive shafts, transmission gears, sprockets, chains, etc. |

| Heat treatment | Annealing, solution, normalizing, tempering, quenching, induction hardening, quenching and tempering |

| Tolerances | ± 0.02 mm |

| Surface treatment | Polishing, electroplating, machining, anodizing, shot peening, sand blasting, galvanizing, oxide, galvanizing, etc. |

| Testing | Three-coordinate measuring machine for testing. Testing machine digital height gauge, caliper, projector, roughness tester, hardness tester, etc. |