Our company also has the most advanced and complete testing equipment in the aluminum single base low pressure casting industry, including spectrometers, metallographic microscopes, tension testers, low-temperature testers, x-ray testers, MPT, UT, CMM, video measuring machines, etc.

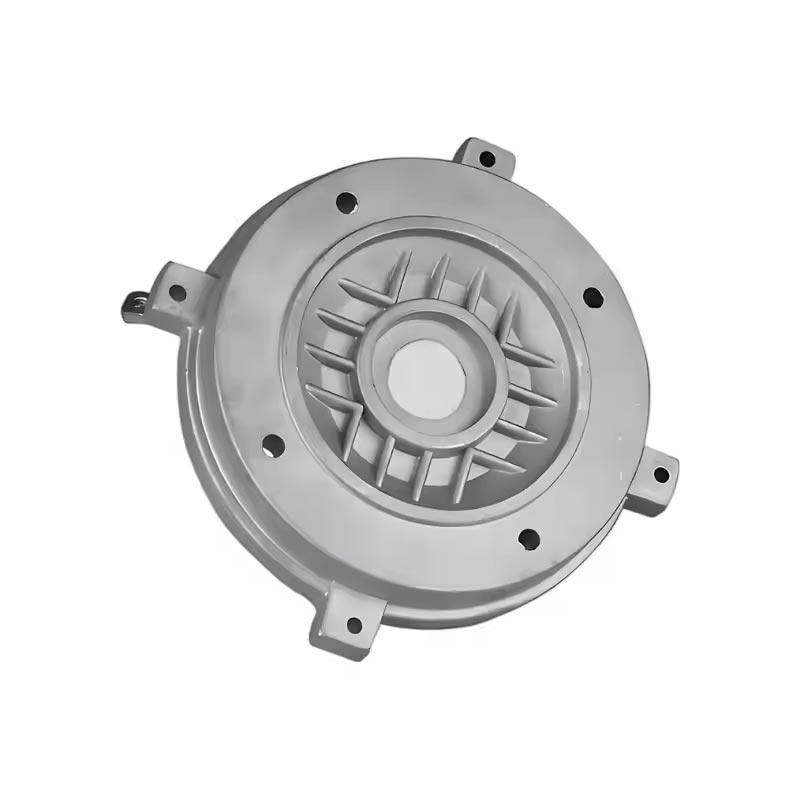

Losier Technology Development Co., Ltd. is a manufacturer and supplier of custom aluminum single base low pressure casting, with a strong product development team with many experienced workers; we are manufacturing custom parts according to your drawings or existing samples.

We can use carbon steel, aluminum, stainless steel, copper, titanium, etc.

Our goal is to develop and produce goods to your exact specifications and provide a wide range of styles to ensure that we can meet your expectations and budget.

Over the years, we have established a quality control system, and our inspectors will carefully check every detail of the product before shipment to ensure that the product is correct according to the requirements.

| Main materials | Mild steel, carbon steel, stainless steel, steel, brass, copper, aluminum, iron, etc. |

| Surface treatment | Polishing, passivation, sandblasting, laser engraving, zinc plating, black oxide, nickel plating, chrome plating, carburizing, powder coating, clear anodizing, color anodizing, sandblasting anodizing, chemical film, brushing, polishing, electroplating gold (ABS), spray painting, brushing (acyl), laser engraving, etc. |

| Technology | Investment casting, precision casting, clay sand casting, resin bonded sand casting, resin sand casting, resin coated sand casting, shell mold casting, pre-coated sand casting, silica sol lost wax investment casting, lost foam casting process, die casting, hot forging, cold forging, etc. |

| Machining | Drilling, reaming and tapping, CNC turning, CNC milling, EDM wire cutting |

| Process | Drawing → mold making → die casting → rough machining → CNC machining → surface treatment → product inspection → packaging → |

| Standards | ISO, GB, DIN, JIS, ANSI, BSW, ASTM, ASME, BS, API, EN |

| Casting tolerances | CT4-CT8 |

| Machining tolerances | +/-0.02 mm |

| Drawings | Required, or provide samples |

| Quality assurance | 100% before shipment QC step inspection |

| File formats | PDF, DWG, DXF, IGES, STEP, XT, etc. |

| Applications | Vehicle parts, LED housing, support bracket, machine parts, motorcycle spare parts, agricultural machinery parts, engineering machinery parts, engine components, aluminum generator spare parts, engine bushings, automobile radiator accessories, power generation industrial parts, engine cylinder block, regulator housing, partitions, crane spare parts, general machinery parts, medical equipment components, scaffolding spare parts, defense components, construction spare parts, mining machinery parts, material handling spare parts, LED cover, LED radiator, water pump spare parts, light box, water pump spare parts assembly, general industrial equipment components, baffles, machine base, automobile suspension spare parts, motor base, truck parts, etc. |

| Packaging | Carton/wooden box/steel pallet or as per customer requirements |

| Delivery times | Mass production takes 35-45 days |

| Ports | Tianjin Port, Tianjin Airport |

With advanced facilities and instruments, we are able to provide customers with the most accurate aluminum single base low pressure casting finished products and make the products meet their requirements for chemical composition, mechanical properties, non-destructive testing and high-precision dimensional inspection.